MKL’s ’98 1200C – Mobil 1 Synthetic Engine Oil Impressions

Pouring in the Mobil 1 Synthetic – 5/00

Background: After reading Donny Petersen’s thorough analysis and comparison of various different motor oils in the March and April 2000 issues of American Iron magazine (AIM), I was convinced that synthetic oil would be a major contribution to the long-term health of my engine. As a test, I switched to Exxon’s Mobil 1 20W/50 Synthetic Motorcycle for V-Twins [NOTE: Petersen’s article tested standard automotive grade Mobil 1 15W/50, which I switched to after my initial test of the V-Twin Blend, with the same results]. The oil change was performed at 14,515 miles and (as usual) included an oil filter change (I use HD’s “Premium” filter).

The Test 5/00: Immediately following the oil change, I left on my way from home in NJ to the 60th Annual Bike Week Rally in Myrtle Beach, SC. The trip proved to be a perfect test, as it involved a wide range of conditions under which the bike was operated, including:

Immediately following the oil change, I left on my way from home in NJ to the 60th Annual Bike Week Rally in Myrtle Beach, SC. The trip proved to be a perfect test, as it involved a wide range of conditions under which the bike was operated, including:

Extended High Speed Highway Riding: I made the trip to and again from SC in 1 day each (~710 miles each way). In both instances, the bike was run for well over 16 hours straight (including very short breaks for fuel, food, and bathroom stops), in wide temperature ranges (from about 45 to 90+ degrees), at an overall average speed of slightly over 60 mph. Actual cruising at speeds ranged between 55 and 80 mph, continuously. Top speeds of over 90 mph were reached and held.

Extended Idling and Slow Creeping (Parade Duty): Once in SC, I participated in the parades on the main drag, where the bike was idling and creeping along below 5 mph for hours, in very high heat (90+). The traffic during Bike Week was pretty intense, so there was a good deal of creeping throughout the trip.

The Bottom Line: In both of the extreme operating conditions described above, the oil temperature reading on my HD dipstick was reduced by 25 degrees to 50 degrees as compared to the benchmark tests which I had conducted earlier using HD’s conventional “360” dyno oil. In fact, during the extended idling and parade duty test, the maximum observed temperature was only 180 degrees using Mobil 1, as compared to the 230 degrees which I used to observe with the HD oil. Temperature during extensive high speed highway riding topped out at 225 degrees with the Mobil 1, but used to top out at 250 using the HD oil. Needless to say, this kind difference is indeed significant, especially considering that the actual temperature of the oil in the engine is approximately 10% higher than the dipstick reads, and that conventional dyno oil starts to break down at 250 degrees! At the end of the grueling 1975 mile Myrtle Beach trip, the Mobil 1 in the oil tank still looked light and clean, and smelled fresh – there was non of the usual browning in color which used to happen with the conventional HD oil.

Side Effects of the Mobil 1: I did not experience any noticeable reduction in valvetrain noise, as some listers have reported. Also, my engine did not start leaking oil – at least, not through any fault of the oil’s. [NOTE: During the trip, the center rocker box cover on the rear cylinder shifted and caused a massive oil leak. This shift was due to the rocker box being improperly torqued down by the last person who touched it, a “certified” HD mechanic, during the S/E head swap.] However, there was one significant side effect – The engine takes much longer to warm up using Mobil 1. The bike needs to run for about 15 minutes, or about 10 miles, before it reaches normal operating temperature or idling speed – this is about twice as long as usual. This can be annoying if you take frequent short trips around town, but I suppose it’s an unavoidable result of Mobil 1’s superior cooling properties.

Cost / Benefit: A 6-can case of Mobil 1 15W/50 as shown above (and as tested in AIM by Donny Petersen) sells for approximately $24 on sale, putting the cost per quart at right around the same level as conventional HD oil. However, judging by the recommended service intervals of other vehicles which use synthetic oil as standard equipment, you can use the synthetic oil for twice as long as conventional. I used to change my HD oil every 2,500 miles – now, I can use the Mobil 1 for a full 5,000 miles. Therefore, it is actually cheaper and less time consuming to use synthetic oil.

Disclaimer: For all interested – you should definitely pick up the aforementioned copies of American Iron magazine, or visit Donny Petersen’s Heavy Duty Cycles, and read up on the subject of oil before deciding to switch to synthetic. The tests I conducted and temperatures I recorded were for a non-stock bike (S/E Head configuration) ridden under extreme conditions – it is perfectly normal for your bike to get different results. However, the general outcome will most likely be the same. In this case, given the real world proof of my tests, I am totally sold on the benefits of synthetic oil, and I plan to use it exclusively in my Sportster from now on.

Addendum I – Short Summary of Petersen’s Article

The end of Petersen’s article has a short conclusion, from which this is quoted directly: “To recap, (good quality) 20W-50 SJ-rated oil is fine for use in your Harley. Airplane oil is a big no-no as far as your Hog is concerned. Synthetic oil is superior to fossil oil after (emphasis added) the engine has been broken in. Top grade modern automotive and motorcycle oils are basically the same. After all, though Harley-Davidson is special in our hearts, in our minds we must realize that The Motor Company didn’t reinvent the air-cooled engine and, therefore, its engines don’t require specially formulated, Harley-only fluids.” Again, I must emphasize that the article in question is extremely detailed with useful practical and technical information, and it must be read to be appreciated.

Update 3/01: Here’s a listing of the relevant articles and dates in which they appeared in American Iron-

AIM March 2000 – “Engine Oils – Are SJ-rated oils okay for your Harley?” by Donny Petersen

AIM April 2000 – “Engine Oil Part II – What is really needed for your H-D” by Donny Petersen

AIM November 2000 – “Open Forum On Oil” by H-D Motor Co.

AIM December 2000 – “The Great Oil Debate: Exxonmobile” by Chuck Goldmann, designer of Mobil 1 V-Twin 20W/50

AIM February 2001 – “The Great Oil Debate: Amsoil” by Ed Newman

AIM March 2001 – “The Great Oil Debate: Torco” by Bob Lancaster, President of Torco

Addendum II – What About the Tranny? 3/01

I received many e-mails inquiring about what lubricant to use in the transmission. As for this, I still use the HD Sport-Trans fluid, which is semi-synthetic. I never had much of a reason to change, since the cost is reasonable and I haven’t read anything objective to suggest that there is a clearly superior product available – although my mind is obviously open to experiment if and when such a product comes to my attention. I do know, however, that several listers (George Crim comes to mind) use Mobil 1 in their tranny as well as their crankcase. YMMV here.

Addendum III – Warranty Issues 9/02

Another very common myth swirling around this issue is that using synthetic oil will void your warranty. Nothing can be further from the truth. So long as you use an oil which meets or exceeds the standards and designations called for in the manual, Harley-Davidson cannot void your warranty, under the Magnusson-Moss Act (MMA). The relevant text of the MMA reads:

“(c) No warrantor of a consumer product may condition his written or implied

warranty of such product on the consumer’s using, in connection with such product,

any article or service (other than article or service provided without charge

under the terms of warranty) which is identified by brand, trade, or corporate name;

except that the prohibition of this subsection may be waived by the Commission

if — (1) the warrantor satisfies the Commission that the warranted product will

function properly only if the article or service so identified is used in connection

with the warranted product, and (2) the Commission finds that such a waiver is in

the public interest.” (42 U.S.C. 2302(C))

Essentially, the MMA specifically prevents manufacturers of OEM vehicles from requiring a consumer to use an OEM part or fluid in order to maintain warranty coverage unless that part or fluid is provide FREE OF CHARGE. (Ever get any free oil from Harley? I never did…) The law is designed to prevent manufacturers from by holding customers hostage by charging obscene prices for parts or fluids which are otherwise commonly available from the aftermarket, assuming a set of minimum standard are met.

Addendum IV – The Debate is Over! 4/03

SYN-3: After many years of myth promotion and fact obfuscation, Harley-Davidson finally introduced its own line of synthetic oil called “SYN-3” in early 2003. Upon reading the announcement in my Spring 2003 supplement, I noticed some interesting tidbits where Harley contradicts many of its earlier anti-synthetic assertions ad nauseum. The supplement boasts of the advantages of SYN-3 as if H-D has just reinvented the wheel. According to the supplement, “current levels of petrochemical technology” have allowed HD engineers a breakthrough, and the new oil supposedly offers increased levels of protection against wide temperature ranges, reduced friction, etc. etc. The same things all other synthetic manufacturers have been claiming for decades. The part of the advertising which irks me is where H-D claims it needed to create a new “performance standard” – dubbed the “Harley-Davidson Screamin’ Eagle Synthetic Motorcycle Lubricant Performance Standard” – by which to judge which synthetic oils are suitable. Naturally, only SYN-3 “meets” this “standard,” which of course isn’t specified. The brochure goes on to claim that SYN-3 “outperformed all other engine oils” in dynamometer tests, and outperforms “any petroleum-based lubricant.” Finally, the brochure refers people with questions to the “Parts Professionals” at the local dealership. The SYN-3 sells for just under $9 per quart, and can be used in both the engine and transmission.

A few comments: Call me cynical, but until I see objective evidence regarding this product’s performance, I wouldn’t even consider buying “Harley’s” synthetic oil. The company has a history of marketing myth over objective fact, and no issue illustrates this more than oil. For years, in the face of all published independent tests, Harley insisted that only its overpriced petroleum-based oil was suitable for its V-Twin motors. The same marketing mill which for years advanced the cause that synthetic was somehow “bad” – as all objective evidence pointed the other way – is now trying to sell the same stuff it once insulted!

There has been no “technological breakthrough.” Synthetic oil has been around for decades, and Harley has finally come to the brilliant conclusion that its customers were being turned onto it due to its functional benefits, and the fact that it typically sells for less than Harley’s petroleum-based “360” product.

There was no need to create a “new” performance standard – this is a blatant marketing move designed to avoid direct comparison between SYN-3 and all of the other established synthetic oils on the market.

That this stuff can be used in both the engine and trans “to avoid confusion or accidentally topping off with the wrong fluid” speaks volumes about just how intelligent HD thinks its average customer is. I don’t get confused that easily, and this supposed “benefit” speaks more to the fact that the viscosities in HD engines and transmissions are close enough to use the same fluid – something which, again, has been done for years already.

There is NO WAY I’m going to a Harley “Parts Professional” – the same exact guys who swore that synthetic oil caused “bearing skate” (while never producing any proof of such a problem) – for advice on why I should now buy Harley oil.

And finally, there is no way I’m paying $9 per quart for SYN-3, which is simply some major $4 per quart brand re-badged and sold at double the price to anyone gullible enough to buy it.

Now, inevitably, newbies will come along unaware of the history, and will buy this overpriced, overmarketed oil – and I find no fault in them for it beyond an inability to gauge value. But to me, anybody who has been around this scene long enough to see the oil thread rear its ugly head, and buys synthetic only now that the H-D marketing machine has granted its permission, has the critical thinking skills of a retarded knat which has just inhaled PCP.

Bottom Line: Until I see objective proof of this product’s performance, I would not consider buying it. But at least now the debate is over – the last stalwart of pro-petroleum marketing has just fallen.

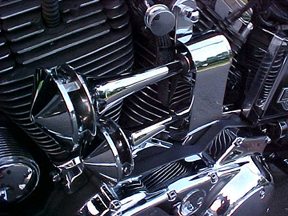

The Dual-Trumpet Assembly Mounts In Stock Location – Finding Space for Compressor Requires Creativity 5/03

Mounting & Installation: Well, let’s just say that if you have a Sportster, it isn’t the “UNDER 20 MINUTES!!” promised on the box the horn arrived in. There are two main parts of this assembly: the dual-trumpet horns and the compressor. The horns mount in the stock “cowbell” horn position. Problem #1 was encountered here, as the chrome washer which goes between the trumpet horn bracket and the stock rubber horn-mount grommet was much too thick, preventing the stock nut from grabbing the stock horn mounting stud when mounting the trumpet assembly. Rather than replace the stud, I took Rivco’s supplied chrome washer down to the local bike shop, where it was milled down by half. Now I could mount easily, using my stock chrome acorn nut and lock-washer (with liberal amounts of Loc-Tite). Problem solved. I should note here that the trumpet assembly is quite top heavy, and is only secured in that one (stock) mounting location spot. In the almost 4,000 miles and three months of testing which preceded this report, the trumpet assembly never moved, so there were no actual issues – but the final assembly still leaves you with a feeling that this isn’t the most robust mounting method.

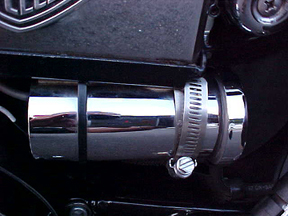

The compressor was next. We all know extra space is hard to find on a Sportster, so I knew this would be a challenge. The most obvious mounting location is right in between the front frame’s two downtubes – I have seen compressors mounted there before on XLs. But on my bike, the engine guard and the chrome voltage regulator cover ate up enough of that small space between the downtubes so as to prevent the compressor from fitting there. In looking around the bike, I decided to use the space available under the battery tray. The compressor comes with one aeroseal to mount, so I widened the existing slot on the right side of the battery tray with a Demel tool, just wide enough to fit the aeroseal. Then, I drilled a hole on the left side of the tray, so I could add a tie-wrap for added support. Finally, I added a strip of rubber between the compressor and the battery tray, to avoid metal to metal contact and scuffing. All worked fine, though now I need to loosen the aeroseal to gain access to the 7/16″ nut which holds the battery strap tight – a very minor inconvenience. Overall, any effort placed here is not the fault of the manufacturer, but instead is an inherent part of owning a motorcycle with limited spare space. There is one gripe, though: The compressor’s optional chrome cover could have been slotted to allow the aeroseal to go inside, rather than completely outside the cover. This would give the product a much more finished appearance – who wants to have a big, ugly aeroseal in plainly obvious sight?

Finally, we have the wiring and associated routing of the air hose. The wiring basically involves plugging the existing power leads for the stock horn into a relay, and then plugging the leads from the compressor into the same relay. The instructions tell you to tie-wrap the black relay box to the backside of trumpet assembly, which is not the most appealing location in terms of aesthetics. Also, given how much the trumpet assembly vibrates at idle, I didn’t want the wiring attached to that location. Rather, I elected to extend the stock horn power leads, and ran all leads up under the seat, where I mounted the relay to the frame with some tie wraps. I sealed all electrical connections with my own shrink-tubing and some dielectric grease, to prevent corrosion in the long term. This took more time, sure, but this is really the right way to do it on this type of bike. The included air-hose was nicely packaged in a protective black mesh, and was easy to run with the stock wiring harness from the compressor to the horn. I secured all air-hose connection points with my own tie-wraps, just for added measure.

Performance: This is one area where there are no complaints. The horn assembly works exactly as advertised, delivering an extremely powerful, ear-piercing blast. In fact, on the highway, it’s quite fun to watch the mindless cell-phone blabbers who wander into your lane or push you off the road go into “emergency swerve” mode at the sound of this horn, which sounds very much like a semi-truck’s. Given that the decibel scale is not linear, I do believe Rivco’s claim of this horn being four times louder than stock (~87 dB) – in the 128 dB range. It really is something else! As part of the test, I also drove with the horn in horrendous downpours for long periods of time, and it kept working fine. A tip for wet weather riding – remember to mount the trumpets facing slightly downward, so water doesn’t puddle in the reeds!

Bottom Line: After using this horn, I can say that having a louder horn is especially useful for commuter / heavy traffic applications, given the dismal rate of awareness of the cagers around you. However, this particular product is not flawless – in addition to the niggling installation issues raised above, the design with regards to horn maintenance is also lacking. Rather than have removable end caps so as to allow easy access to the reeds (for cleaning), you must physically disconnect the horn and squirt WD-40 into the air-hose, and then blow that out with the compressor. Again, this is a design flaw which could make the product that much better if addressed.

As I was testing this product, a similar dual-trumpet design came out from a company called Howard’s Horns. The Howard’s Horns unit does have removable end caps for easy access to the reeds, and has a different mounting process which may or may not be better for the Sportster (no direct comparison available because I haven’t seen one in person). Also, if the performance is all that matters and you can live without chrome, you can pick up a bargain air-horn assembly (with compressor) from JC Whitney or other auto-parts warehouse for about $60.00, which will essentially do the same thing as the fancy chrome units do.